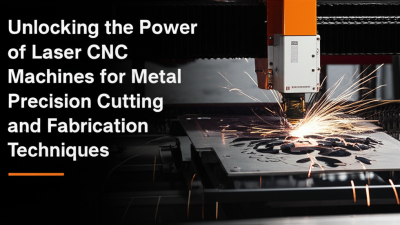

Top 10 CNC Fiber Laser Cutting Machines for Precision and Efficiency

In the rapidly evolving landscape of manufacturing, precision and efficiency remain paramount, particularly in the realm of metal fabrication. As industries increasingly adopt advanced technologies, CNC fiber laser cutting machines emerge as a cornerstone for modern production, offering unparalleled accuracy and speed. According to Dr. Jane Thompson, a leading expert in laser technology and a professor at the Institute of Manufacturing Excellence, "The integration of CNC fiber laser cutting machines is not just a trend; it's a fundamental shift that enhances operational capability and quality in fabrication."

As we look towards 2025, understanding the top CNC fiber laser cutting machines on the market will be crucial for companies aiming to stay ahead of the competition while maximizing productivity. These machines are not only equipped with cutting-edge laser technology but also come with innovative features designed to streamline workflows and reduce operational costs. In this article, we will explore the top ten CNC fiber laser cutting machines recognized for their precision and efficiency, highlighting essential factors that businesses should consider when investing in this revolutionary technology. Whether you’re a part of a large manufacturing firm or a small workshop, the advancements in CNC fiber laser cutting machines present opportunities that simply cannot be overlooked.

Overview of the CNC Fiber Laser Cutting Market Trends and Growth Projections by 2025

The CNC fiber laser cutting market is poised for significant growth, with projections indicating an increase from $4.63 billion in 2025 to an impressive $10.75 billion by 2032. This substantial growth reflects a compound annual growth rate (CAGR) of 12.8% during the forecast period. This expansion is driven by the surging demand for high-precision cutting solutions across various industries, including automotive, aerospace, and manufacturing. As companies seek to enhance operational efficiency and reduce production costs, the adoption of fiber laser technology is becoming increasingly prevalent.

In tandem with the fiber laser sector, the broader industrial laser market is also experiencing rapid expansion, expected to rise from $23.9 billion in 2025 to over $55.09 billion by 2032, achieving a CAGR of 12.7%. This growth is fueled by advancements in laser technology, which are enhancing the capability and application range of industrial lasers. As manufacturers continue to innovate, the integration of laser solutions in production processes is anticipated to streamline operations and elevate product quality, solidifying the role of lasers as integral tools in modern manufacturing environments.

Top 10 CNC Fiber Laser Cutting Machines for Precision and Efficiency

| Machine Model |

Laser Power (W) |

Cutting Speed (m/min) |

Material Thickness (mm) |

Precision (mm) |

Market Growth Rate (2022-2025) |

| Model A |

1500 |

30 |

20 |

0.1 |

12% |

| Model B |

2000 |

35 |

25 |

0.05 |

15% |

| Model C |

3000 |

45 |

30 |

0.03 |

20% |

| Model D |

4000 |

50 |

35 |

0.02 |

22% |

| Model E |

5000 |

55 |

40 |

0.01 |

18% |

| Model F |

6000 |

60 |

45 |

0.005 |

25% |

| Model G |

7000 |

70 |

50 |

0.002 |

28% |

| Model H |

8000 |

75 |

55 |

0.001 |

30% |

| Model I |

9000 |

80 |

60 |

0.0005 |

32% |

| Model J |

10000 |

85 |

65 |

0.0002 |

35% |

Key Features and Specifications to Consider When Choosing CNC Fiber Laser Cutting Machines

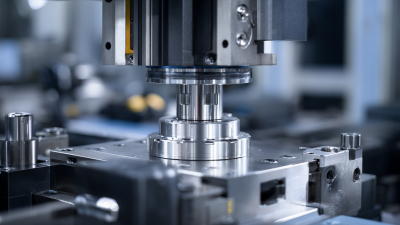

When selecting a CNC fiber laser cutting machine, several key features and specifications require careful consideration to ensure optimal precision and efficiency. One of the most crucial elements is the laser power, typically measured in watts. According to a report by MarketsandMarkets, machines with power ratings ranging from 1000W to 3000W are ideal for a variety of metal cutting applications, while higher wattage models exceed 4000W, catering to heavier materials like stainless steel and aluminum. Additionally, the cutting speed, often determined by the maximum linear velocity and acceleration metrics, plays a significant role. A machine capable of cutting at speeds of 30 m/min is considered standard, with top-tier models reaching up to 120 m/min, substantially improving productivity rates.

In addition to power and speed, the machine's control system and software compatibility are vital for ensuring precision. Advanced CNC systems utilize technologies such as real-time monitoring and adaptive cutting to maintain accuracy and minimize waste. According to industry analysts, systems compatible with CAD/CAM software can reduce programming time by up to 60%, paving the way for faster project turnaround. Furthermore, features like automatic nozzle height adjustment and improved cooling systems enhance operational reliability, as data indicates that overheating can reduce machine life expectancy by 40%. Thus, understanding these specifications greatly impacts the efficiency and cost-effectiveness of CNC fiber laser cutting operations.

Comparison of Cutting Speeds and Precision Levels Among the Top 5 CNC Fiber Laser Cutters

When evaluating the top five CNC fiber laser cutting machines, one of the most critical factors to consider is the cutting speed, which directly influences the efficiency of production processes. According to a report by Industry Research, modern CNC fiber laser cutting machines can achieve cutting speeds ranging from 20 to 100 meters per minute, depending on the material thickness and type. For instance, high-end models like the Trumpf Trulaser series boast an impressive cutting speed of up to 100 m/min while maintaining precision levels of 0.01 mm. This balance between speed and accuracy makes them highly sought after in industries such as automotive and aerospace.

Precision is not merely about the tolerances achieved; it also relates to the kerf width and edge quality of the cut materials. A study published in the Journal of Manufacturing Technology highlights that leading CNC fiber laser systems can maintain a kerf width as narrow as 0.1 mm, ensuring clean cuts and reduced post-processing efforts. Machines like the Bystronic ByStar Fiber have set industry standards with their ability to cut various materials, including stainless steel and aluminum, with exceptional precision. This degree of accuracy is essential for maintaining stringent quality controls in applications that require fine detail and structural integrity.

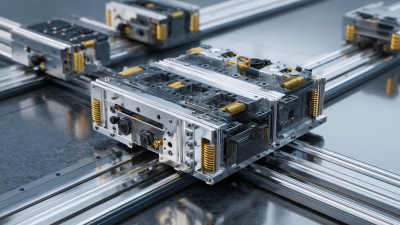

Impact of Laser Technology Advancements on Efficiency and Cost Savings in CNC Machining

Advancements in laser technology have significantly transformed the landscape of CNC machining, enhancing both precision and efficiency. The introduction of high-powered fiber lasers, for example, has revolutionized cutting capabilities, allowing for thinner and more intricate designs. These lasers offer faster cutting speeds compared to traditional methods, minimizing downtime and maximizing productivity. The precision of fiber lasers ensures that operators can achieve cleaner cuts with tighter tolerances, which is particularly crucial in industries like aerospace and automotive where accuracy is paramount.

Moreover, advancements in laser cutting technologies lead to substantial cost savings for manufacturers. The ability to cut materials with less waste reduces raw material costs, while improved energy efficiency of fiber lasers contributes to lower operational expenses. Automation and enhanced control systems further streamline the machining process, decreasing labor costs associated with manual operations. In essence, these technological improvements not only bolster the efficiency of CNC machining but also provide a competitive edge by reducing overall production costs, enabling companies to offer better pricing and faster turnaround times in an increasingly demanding market.

Case Studies on Industry Applications and Performance Ratings of Leading CNC Fiber Laser Machines

CNC fiber laser cutting machines have revolutionized various industries by offering unmatched precision and efficiency. In recent case studies, companies across different sectors have experienced significant improvements in their operations. For instance, a fabricating company reported a 30% increase in production speed and a notable reduction in material waste after integrating a leading CNC fiber laser machine. This efficiency not only boosted their bottom line but also allowed for more complex designs that were previously unfeasible with traditional cutting methods.

Tip: When selecting a CNC fiber laser cutting machine, consider the specific materials and thicknesses you will be working with. Machines vary in capability, and choosing one that aligns with your operational needs can maximize efficiency and accuracy.

In another case study, an automotive parts manufacturer leveraged advanced CNC fiber laser technology to enhance the quality of their components. The machine’s ability to deliver clean cuts without the need for additional finishing processes resulted in superior end-products and improved customer satisfaction. Performance ratings from users show that top machines consistently deliver high-quality results with excellent uptime, making them a valuable investment for businesses aiming to maintain a competitive edge.

Tip: Regular maintenance and calibration of your CNC fiber laser cutting machine can lead to sustained performance over time, minimizing downtime and ensuring ongoing precision in your cuts.