2025 Top 5 Small Laser Cutting Machines for Precision and Performance

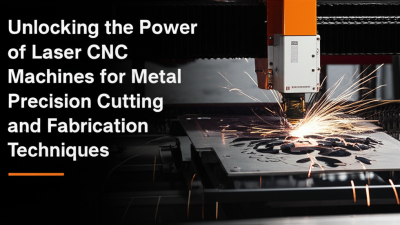

In the rapidly evolving landscape of manufacturing technology, small laser cutting machines have emerged as critical tools for achieving precision and performance in various applications. According to a recent report by MarketsandMarkets, the global laser cutting machine market is projected to grow from $3.1 billion in 2020 to $4.9 billion by 2025, highlighting a significant interest in compact solutions that deliver high-quality cuts. As industries increasingly seek to optimize their processes while maintaining cost efficiency, small laser cutting machines are playing an integral role in this transition.

Industry expert Dr. Emily Chen, a leading figure in laser technology research, emphasizes, "The advancement of small laser cutting machines is revolutionizing how small to medium enterprises approach manufacturing, offering precision that was once only achievable with larger systems." This shift towards smaller, more efficient machines allows businesses to enhance their production capabilities without the overhead costs associated with larger equipment.

As we explore the top five small laser cutting machines of 2025, it becomes evident that these tools are not only beneficial for their size but also for their ability to deliver exceptional performance, catering to the precise needs of modern manufacturing. These advancements signify a pivotal change in how we perceive cutting technologies and their application across various industries.

Top Features to Look for in Small Laser Cutting Machines

When selecting a small laser cutting machine, it's essential to focus on key features that guarantee precision and performance. One of the most significant aspects to consider is the laser type—CO2 lasers are popular for cutting a wide range of materials, including wood, acrylic, and fabric. On the other hand, fiber lasers excel in cutting metals like stainless steel and aluminum. Understanding your primary materials will help you choose the right laser type for your projects.

Another crucial feature is the machine's wattage, which directly influences cutting speed and depth. Higher wattage typically results in faster cutting speeds and the ability to handle thicker materials. Additionally, look for machines with advanced control systems that allow for intricate designs and settings adjustments.

Tips: Always check for software compatibility, as a user-friendly interface can significantly streamline your workflow. Moreover, consider investing in machines with good customer support and community resources for troubleshooting and maximizing machine capabilities. Lastly, examine the machine's working area; a larger workspace enables more extensive projects without frequent repositioning.

Comparative Analysis of Performance Specifications in 2025 Models

In the rapidly evolving market of small laser cutting machines, the 2025 models showcase impressive advancements in both precision and performance. A comparative analysis of their performance specifications reveals distinct features tailored to meet the diverse needs of industries ranging from arts and crafts to heavy manufacturing. Key contenders in this category boast enhanced cutting speeds and finer resolution, enabling users to achieve intricate designs with minimal post-processing.

Among the top five models, the integration of cutting-edge technology such as AI-driven software ensures optimized performance during operation. Additionally, factors like material versatility and energy efficiency are critical criteria for evaluation. For instance, some machines are specifically engineered to cut through a broader range of materials, including metals and plastics, while simultaneously maintaining a lower power consumption rate. This analysis not only highlights the capabilities of each machine but also offers insights into future trends in laser cutting technology, emphasizing the importance of precision engineering in modern manufacturing processes.

Cost-Effectiveness: Budgeting for Your Laser Cutting Needs

When considering small laser cutting machines in 2025, cost-effectiveness emerges as a critical factor for businesses seeking to maximize their return on investment. Budgeting for laser cutting needs involves understanding the initial acquisition costs, operational expenses, and potential savings achieved through improved efficiency. Selecting a machine that balances quality with affordability can significantly impact overall profitability, making it imperative to conduct thorough research and comparisons before making a purchase.

In addition to upfront costs, businesses should evaluate ongoing expenses such as maintenance, material consumption, and energy usage. Investing in a reliable and efficient laser cutting machine minimizes downtime and reduces waste, directly influencing the bottom line. By leveraging advanced technologies that enhance performance, even smaller companies can compete with larger firms while maintaining a budget-friendly approach. Thus, prioritizing cost-effectiveness in budgeting for laser cutting machines not only ensures immediate financial viability but also supports long-term growth and adaptability in an ever-evolving market.

2025 Top 5 Small Laser Cutting Machines for Precision and Performance - Cost-Effectiveness: Budgeting for Your Laser Cutting Needs

| Model |

Cutting Area (mm) |

Max Power (W) |

Material Compatibility |

Price (USD) |

| LaserPro X1 |

600 x 400 |

120 |

Acrylic, Wood, Fabric |

1,200 |

| MiniCut Pro |

500 x 300 |

80 |

Wood, Cardboard, Acrylic |

900 |

| FlexiLaser 2025 |

800 x 600 |

150 |

Fabric, Leather, Plastic |

1,800 |

| ProLaser Econo |

400 x 300 |

60 |

Paper, Cardboard |

600 |

| SmartCut 250 |

700 x 500 |

100 |

Wood, Acrylic, Glass |

1,500 |

Essential Maintenance Tips to Ensure Longevity and Precision

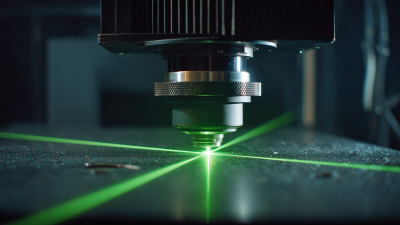

Proper maintenance of small laser cutting machines is essential for ensuring their longevity and precision. Regular cleaning of the machine components, especially the lens and mirrors, is crucial to maintain optimal performance. Dust and residue can obstruct the laser beam, resulting in reduced cutting quality and increased wear on the equipment. It’s recommended to use specialized cleaning solutions and soft cloths to avoid scratching delicate surfaces.

In addition to cleaning, regular inspections of the machine's alignment and focusing are vital. Misalignment can lead to uneven cuts and excessive machine strain, which may shorten its lifespan. Users should also keep an eye on the cooling system, ensuring it operates effectively to prevent overheating. By adopting a proactive maintenance schedule, operators can not only enhance the precision of their cuts but also extend the service life of their laser cutting machines, maximizing their investment and efficiency in operations.

2025 Top 5 Small Laser Cutting Machines for Precision and Performance

This chart illustrates the cutting precision of the top 5 small laser cutting machines in 2025, measured in millimeters (mm). Ensuring precision is crucial for performance and overall longevity of the machines.

User Reviews: Real-World Performance Insights on Top Models

When considering the best small laser cutting machines for

precision and performance, user reviews provide

invaluable insights into real-world applications. Customers frequently emphasize the importance of

consistent cut quality and the machine's ability to handle

a variety of materials. Users of models like the Glowforge Pro rave about its excellent user

interface and versatile capabilities, allowing for intricate designs in wood, acrylic, and even leather

with great accuracy. They appreciate the seamless integration of design software, which enhances usability

for both beginners and experienced crafters alike.

On the other hand, the Epilog Zing and Boss LS machines receive high marks for their

durability and reliability in a more industrial setting. Users often report that these machines operate

quietly and efficiently, making them suitable for ongoing small business applications. Additionally,

feedback highlights robust customer service and community support,

which are crucial for those navigating their first laser cutting experience. Such real-world

performance insights help potential buyers gauge the practicality and value of each model, ensuring they

choose a machine that meets their specific needs.