2025 Top 5 Linear Motor System Innovations That Will Transform Industries

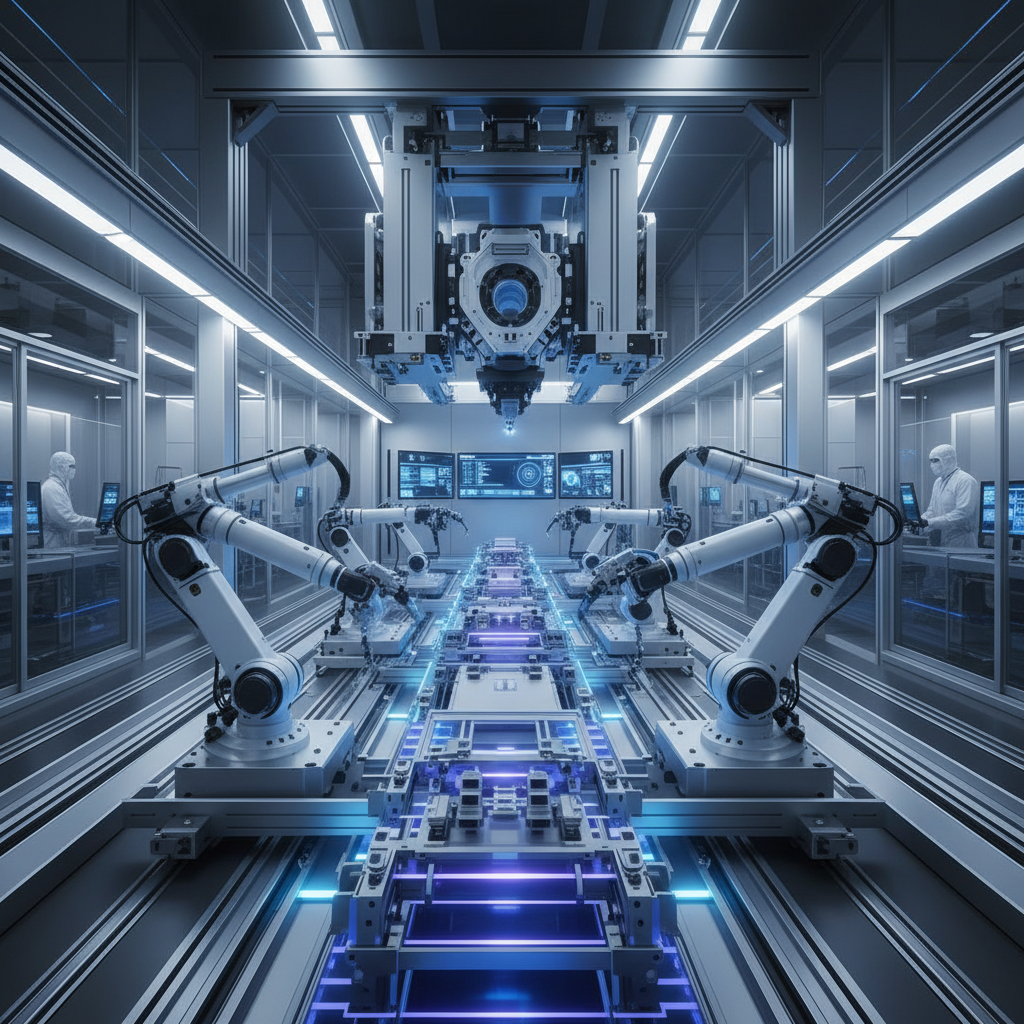

In recent years, the evolution of technology has paved the way for remarkable innovations across various industries. One of the most significant advancements is in the realm of linear motor systems, which are redefining manufacturing and automation processes. As the demand for precision, efficiency, and flexibility grows, linear motor systems have emerged as a cornerstone for modern automation, offering direct drive solutions that eliminate the need for traditional mechanical components. This technology is not only reshaping the landscape of automation but is also setting new standards in speed and performance.

As we look forward to 2025, several key innovations in linear motor systems are anticipated to make a considerable impact on diverse sectors. These breakthroughs promise to enhance productivity and streamline operations, driving industries toward a future characterized by intelligent automation and enhanced operational capabilities. This article will explore the top five innovations in linear motor systems poised to transform industries, showcasing how these advancements will integrate seamlessly with emerging technologies and redefine the benchmarks of industrial excellence. Embracing these innovations will be essential for companies aiming to stay competitive in an ever-evolving market that prioritizes efficiency and adaptability.

Advancements in Linear Motor Efficiencies: Paving the Way for Greater Productivity

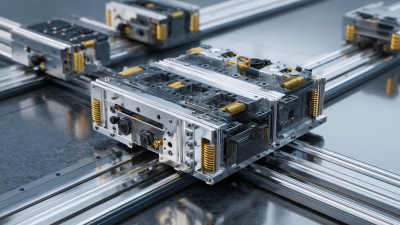

The advancements in linear motor efficiencies are set to revolutionize various industries by enhancing productivity and reducing operational costs. Linear motors, with their direct-drive capabilities, eliminate the need for conventional mechanical components such as gears and belts. This leads to greater reliability and reduced maintenance, allowing industries to focus their resources on core production tasks. The improved efficiency of these motors ensures that machines can operate at higher speeds and with greater precision, which boosts overall throughput.

Moreover, innovations in materials and design are driving the performance of linear motors to new heights. By incorporating high-performance magnets and advanced control systems, manufacturers are achieving unprecedented levels of energy efficiency. These developments not only decrease energy consumption but also lower the carbon footprint of industrial operations. As a result, businesses are better positioned to meet sustainability goals while simultaneously increasing their competitive edge in a rapidly evolving market. The fusion of efficiency and productivity heralds a new era for industries reliant on linear motors.

Impact of Linear Motors on Automation in Manufacturing: Case Studies and Industry Trends

The impact of linear motors on automation in manufacturing is becoming increasingly significant. According to a report by Research and Markets, the global linear motor market is expected to grow from $2.3 billion in 2020 to $3.8 billion by 2025, representing a CAGR of approximately 11%. This growth is driven by the demand for high-speed motion control and greater accuracy in manufacturing processes. Linear motors, with their direct drive technology, eliminate the need for mechanical components like gearboxes, enhancing efficiency and reducing maintenance costs.

Case studies illustrate how companies are leveraging linear motor systems to transform their operations. For instance, a leading automotive manufacturer adopted linear motors for its assembly line, resulting in a 30% reduction in cycle times. This not only improved production efficiency but also allowed for a more flexible manufacturing approach, reducing lead times for new product launches. Furthermore, the integration of linear motors in semiconductor fabrication plants has led to unprecedented precision, with positioning accuracy improvements of up to 50% over traditional systems. As industries continue to embrace these innovations, the role of linear motors in driving automation and enhancing productivity will only grow.

Predictive Maintenance Through Smart Linear Motors: Reducing Downtime and Costs

The rise of smart linear motors in industrial applications is fundamentally reshaping

predictive maintenance strategies, enabling companies to significantly reduce downtime

and operational costs. According to a report by MarketsandMarkets, the predictive maintenance market is projected to reach

$23.5 billion by 2026, with a compound annual growth rate (CAGR) of 28.5%

from 2021. This growth underscores the urgent need for industries to adopt advanced technologies like smart linear motors, which offer

real-time data tracking and analytics capabilities.

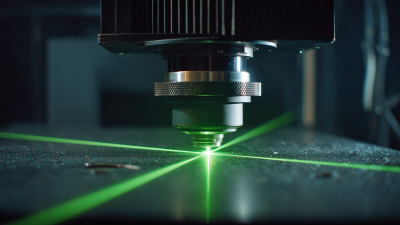

Smart linear motors equipped with sensors provide seamless monitoring of operational parameters such as

temperature, vibration, and

performance efficiency. By leveraging this data, predictive maintenance can be

implemented, allowing for proactive rather than reactive repairs. A study conducted by Deloitte suggests that early detection

of potential failures through predictive analytics can save companies between 10% to 30% on

maintenance costs. This not only enhances equipment reliability but also boosts overall productivity by minimizing unplanned

shutdowns, which can cost manufacturers up to $260,000 per hour in lost production,

as noted by IndustryWeek. Thus, integrating smart linear motors into operational frameworks positions industries for substantial

economic benefits and a competitive edge in their respective markets.

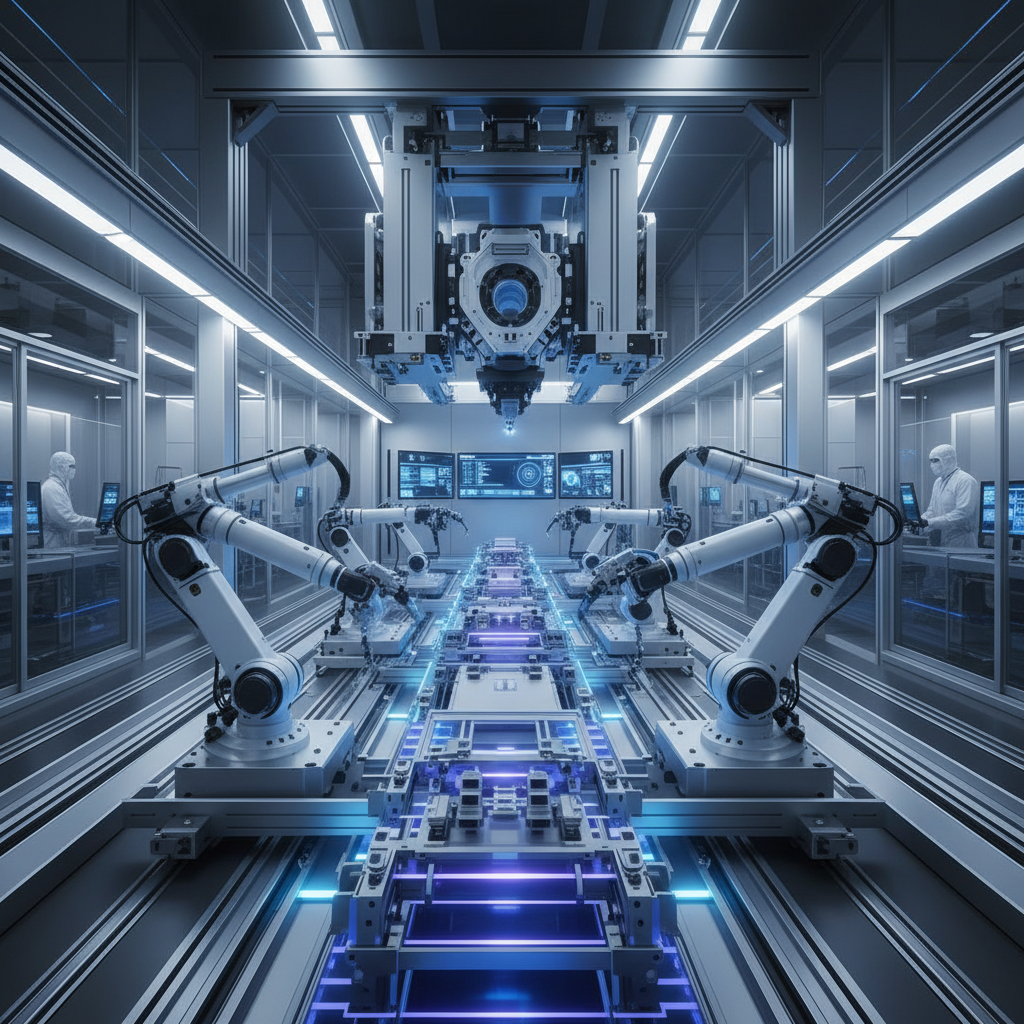

Integration of Linear Motor Technologies in Robotics: Enhancing Precision and Performance

The integration of linear motor technologies in robotics marks a pivotal advancement in enhancing precision and performance across various industries. Traditional motors often face limitations in speed and accuracy, hindering their effectiveness in high-demand applications. With the adoption of linear motors, robotic systems can achieve faster response times and more precise movements, which are crucial for tasks such as assembly, machining, and intricate manipulations.

One of the most significant benefits of linear motors is their direct drive mechanism, which eliminates the need for mechanical components like gears and belts. This not only reduces wear and tear but also minimizes backlash, resulting in smoother and more reliable operations. As industries increasingly rely on automation, the deployment of linear motor systems is set to redefine robotic capabilities, allowing machines to perform with unprecedented finesse. In applications ranging from aerospace to medical devices, the enhanced motion control offered by linear motors will likely foster innovations that improve efficiency and outcomes, ultimately transforming the way industries operate.

2025 Top 5 Linear Motor System Innovations That Will Transform Industries

| Innovation |

Key Features |

Impact on Robotics |

Projected Adoption Rate (%) |

| Ultra-Precision Linear Motors |

Sub-micron resolution, low back EMF |

Increased accuracy in automated assembly |

75% |

| Integrated Sensor Technologies |

Real-time feedback, temperature compensation |

Enhanced control and response times |

80% |

| Modular Linear Motion Systems |

Flexible configurations, easy scalability |

Versatility in robotic applications |

85% |

| Advanced Cooling Techniques |

Cryogenic cooling, liquid cooling solutions |

Prolongs operational life, heavy-load handling |

70% |

| Wireless Control Systems |

IoT integration, remote monitoring |

Increases automation and reduces wiring |

60% |

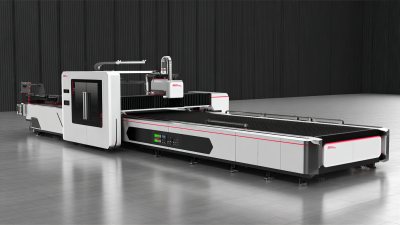

Emerging Applications of Linear Motors in Transportation: Revolutionizing Logistics and Supply Chains

Linear motors are emerging as a transformative force in transportation, particularly in logistics and supply chain operations. Their capacity for high-speed and direct drive mechanisms allows for more efficient movement of goods, reducing transit times and increasing reliability. With applications ranging from automated guided vehicles (AGVs) to high-speed rail systems, linear motors can streamline processes, enhance productivity, and lower operational costs. As industries seek faster and more efficient transportation solutions, linear motors are poised to replace traditional systems, fostering innovation and growth across various sectors.

Moreover, the integration of linear motors into logistics facilitates real-time tracking and smart routing, which are critical for modern supply chains. By minimizing friction and maintenance concerns, these systems ensure that goods are delivered on time while also enhancing safety through precise control. As businesses continue to adapt to the demands of e-commerce and global trade, the implementation of linear motors will revolutionize the logistics landscape, creating a more responsive and agile supply chain. The shifts towards automation and electrification in transportation are set to redefine industry standards, positioning linear motor technology at the forefront of this transformation.