Revolutionizing Automation: How Linear Motor Drives Enhance Precision and Efficiency

The automation landscape is rapidly evolving, and at the forefront of this revolution are

linear motor drives, which significantly enhance

precision and efficiency

in various industrial applications. According to a recent report by Mordor Intelligence, the global linear

motor market is expected to reach

USD 9.74 billion by 2026, growing at a CAGR of

8.12% from 2021 to 2026. This surge in adoption

is largely attributed to the increasing demand for high-speed and high-precision motion systems in sectors

such as manufacturing, packaging, and robotics.

Linear motor drives offer unparalleled advantages, including

reduced mechanical wear and tear,

minimal maintenance requirements, and

superior speed control. As industries strive

to improve productivity and optimize their operations, the integration of linear motor technology

stands as a defining factor in achieving these goals, setting a new standard for

automation solutions.

The Evolution of Linear Motor Drives in Industrial Automation

The evolution of linear motor drives is playing a pivotal role in advancing industrial automation. As precision and efficiency become paramount, linear motors have emerged as a transformative technology. The global linear motion system market is projected to grow significantly, with estimates predicting an increase from USD 12.85 billion in 2025 to USD 22.92 billion by 2033, showcasing a robust CAGR of 7.5%. This growth reflects the increasing demand for high-precision automation in sectors such as manufacturing and logistics.

Parallel to this, advancements in motion control systems, including the development of servo motors, are reshaping the landscape of high-speed automation. The servo motors and drives market is poised for considerable expansion, with a projected value of $21.44 billion by 2031, growing at a CAGR of 5.8%. Innovations in these domains, coupled with trends prioritizing sustainability and energy efficiency highlighted at recent industry events, underline the critical nature of these technologies in meeting the needs of modern automation. As the industry continues to evolve, linear motor drives will undoubtedly remain at the forefront of enhancing operational performance and reliability.

Key Advantages of Linear Motor Drives for Enhancing Precision

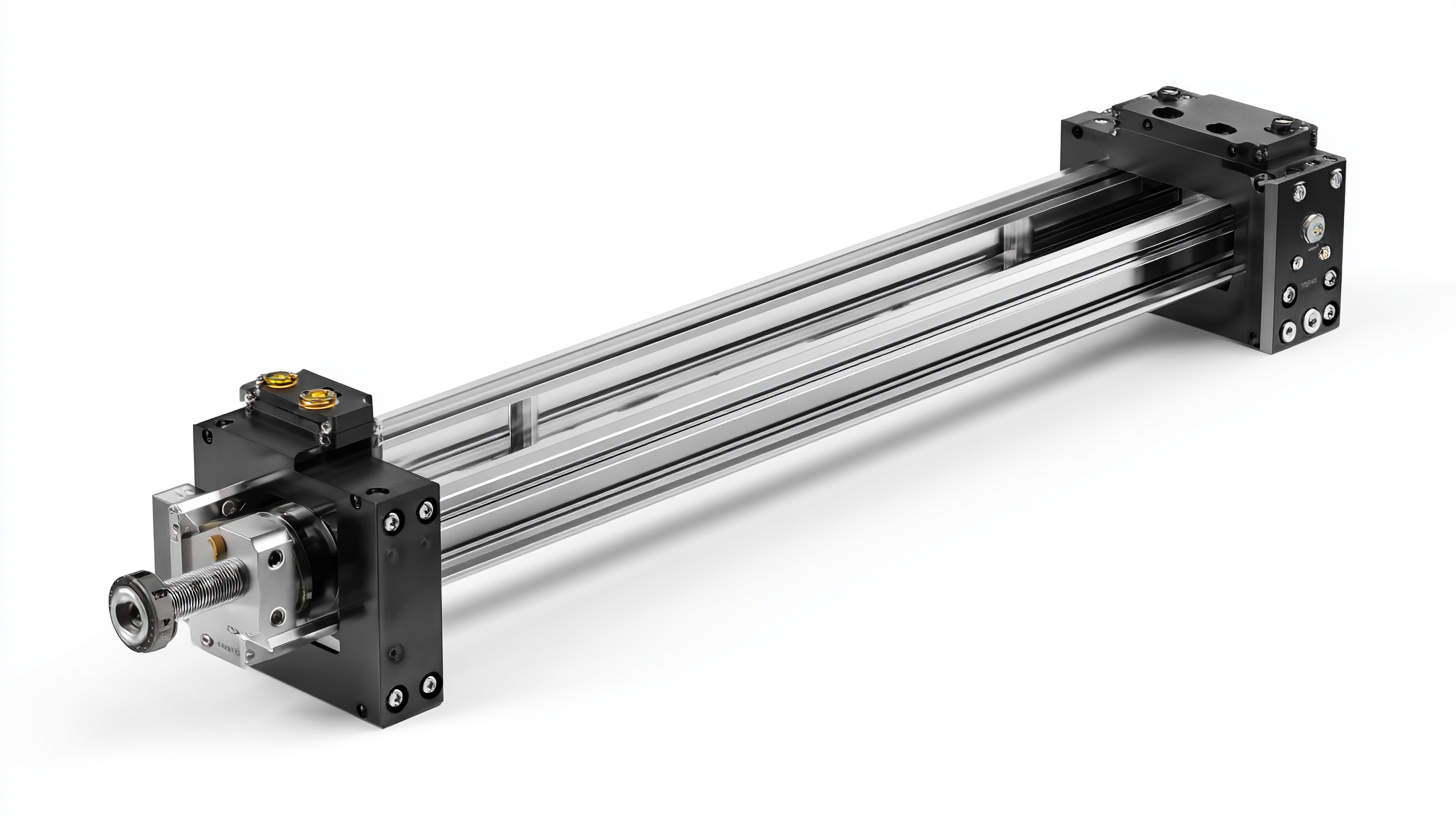

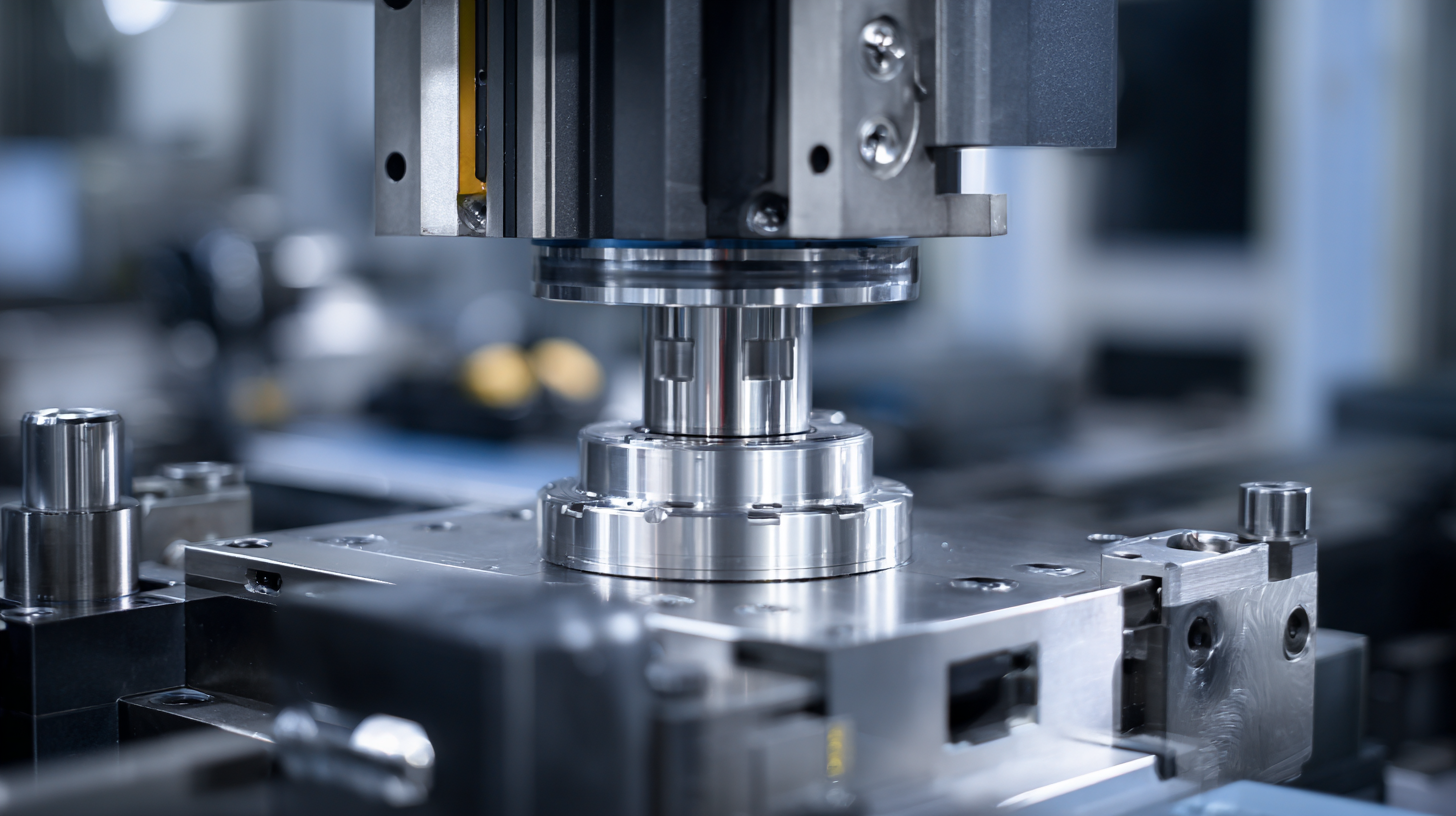

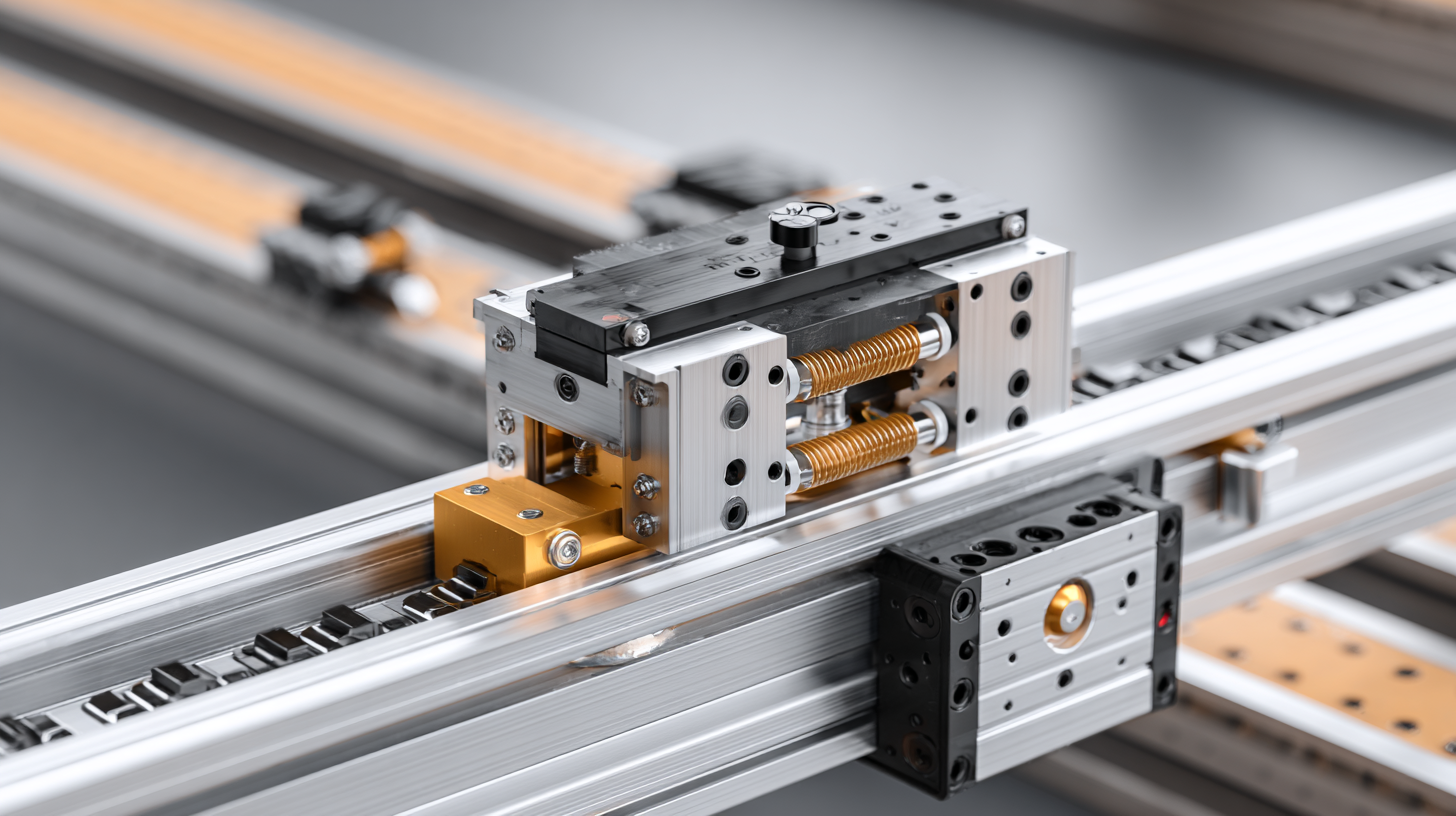

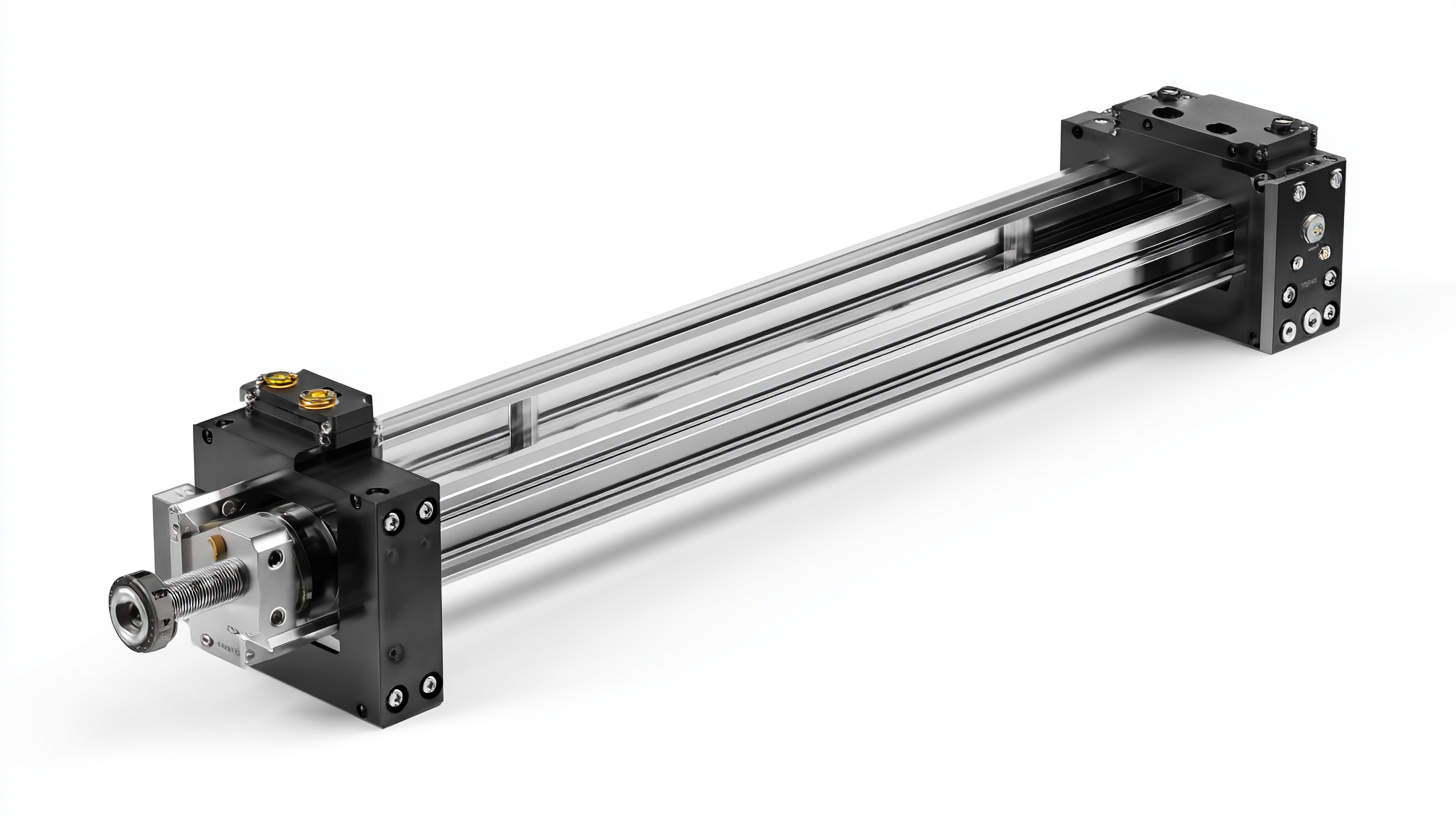

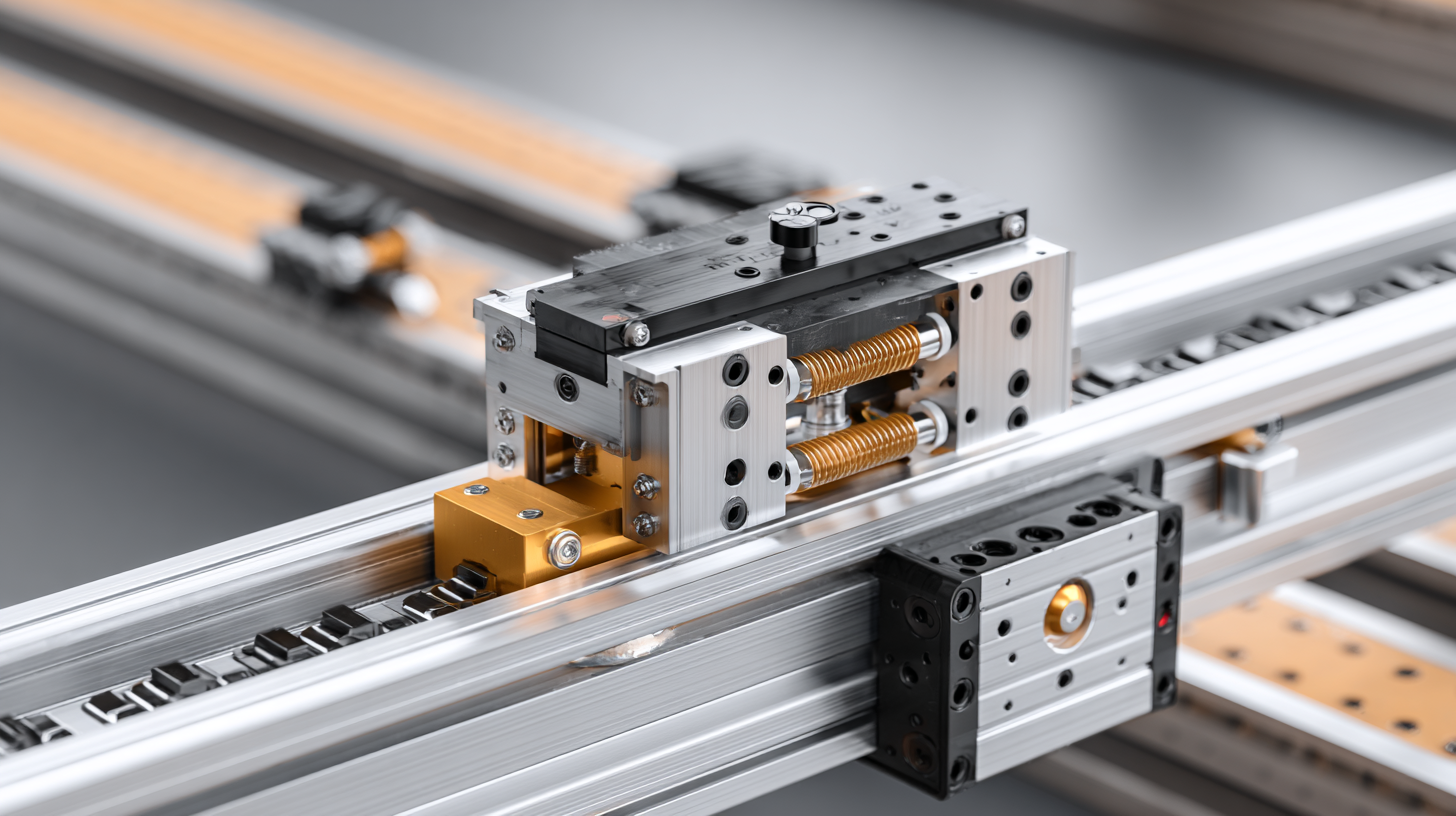

Linear motor drives are at the forefront of automation technology, bringing significant advancements in precision and efficiency. One of the key advantages of these drives is their direct drive mechanism, which eliminates the need for mechanical components such as gears and belts. This results in reduced friction and wear, providing smoother motion and higher accuracy in positioning. The ability to achieve sub-micron precision makes linear motor drives ideal for applications in fields like robotics, semiconductor manufacturing, and medical devices.

Moreover, linear motor drives offer rapid acceleration and deceleration capabilities, which enhance overall productivity. The quick response time enables systems to adapt swiftly to changing demands without sacrificing precision. This dynamic performance is particularly beneficial in high-speed assembly lines and intricate machining processes where both speed and accuracy are paramount. By integrating linear motor drives, industries can not only optimize operational efficiency but also improve product quality, underscoring their pivotal role in modern automation solutions.

Revolutionizing Automation: How Linear Motor Drives Enhance Precision and Efficiency - Key Advantages of Linear Motor Drives for Enhancing Precision

| Dimension |

Linear Motor Drive A |

Linear Motor Drive B |

Linear Motor Drive C |

| Maximum Speed (m/s) |

5.0 |

6.5 |

4.8 |

| Positioning Accuracy (µm) |

2 |

1.5 |

2.5 |

| Maximum Load Capacity (kg) |

100 |

80 |

120 |

| Energy Efficiency (%) |

85 |

90 |

87 |

| Response Time (ms) |

10 |

8 |

12 |

Efficiency Gains: How Linear Motor Drives Transform Operational Performance

Linear motor drives have emerged as a transformative technology in industrial automation, significantly enhancing operational performance across various sectors. According to a report by MarketsandMarkets, the global linear motor market is projected to reach $6.99 billion by 2025, with a compound annual growth rate (CAGR) of 8.5%. This growth is primarily driven by the increasing demand for high-speed and high-precision manufacturing processes. Linear motors offer distinct advantages over traditional rotary systems, including reduced friction, eliminated backlash, and improved accuracy, leading to efficiency gains that many industries are eager to capitalize on.

In practical applications, linear motor drives have demonstrated remarkable improvements in production times and energy efficiency. A study conducted by the International Federation of Robotics indicated that automation utilizing linear motor technology can reduce cycle times by up to 30% while decreasing energy consumption by 20% compared to conventional systems. These enhancements not only streamline manufacturing operations but also contribute to sustainability goals by lowering overall carbon footprints. As industries continue to adopt linear motor drives, the potential for operational efficiency will likely continue to expand, positioning this technology at the forefront of automation solutions.

Applications of Linear Motor Technology in Various Industries

Linear motor technology is making significant strides across various industries, particularly in manufacturing and automation. These motors, which provide direct motion without the need for gears or belts, enhance precision by minimizing mechanical play and backlash. This is particularly advantageous in sectors such as semiconductor fabrication, where minute tolerances are critical. The use of linear motor drives allows for faster processing speeds and improved accuracy, resulting in higher-quality end products and reduced operational costs.

In automation environments, linear motors facilitate advanced robotics and material handling solutions. Industries ranging from automotive to packaging rely on the smooth, uninterrupted motion provided by these systems. For instance, in the automotive sector, linear motors are employed in assembly lines to automate the movement of heavy parts, enabling faster production cycles. Similarly, in the packaging industry, linear drives enhance the efficiency of machines that require precise positioning for labeling and filling. The versatility and efficiency of linear motors are transforming workflows, paving the way for a future where precision and agility are paramount in industrial applications.

Future Trends in Automation: The Role of Linear Motors in Smart Manufacturing

In recent years, linear motors have emerged as a game-changer in the field of smart manufacturing, offering unparalleled precision and efficiency in automation processes. According to a report by MarketsandMarkets, the global linear motor market is expected to reach approximately $5.9 billion by 2025, growing at a CAGR of 7.2%. This growth can be attributed to the increasing demand for high-speed automation and the need for accurate positioning systems across various industries. Linear motors provide a direct-drive solution that eliminates gears and belts, significantly reducing mechanical friction and wear, thereby enhancing overall system reliability.

Moreover, the integration of linear motors into smart manufacturing not only improves precision but also enables advanced automation techniques such as IoT-enabled processes and real-time monitoring. A study published by the International Federation of Robotics suggests that smart manufacturing solutions, including linear motor drives, could boost productivity by up to 30% while cutting operational costs by as much as 20%. This trend highlights the critical role linear motors play in the evolution of automation technologies, paving the way for more agile and responsive manufacturing environments in the future.