Why You Should Choose a Home Laser Cutter Machine for Your DIY Projects

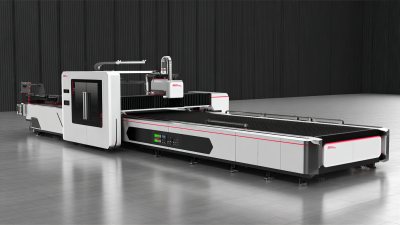

In the realm of DIY projects, creativity knows no bounds, and having the right tools can significantly elevate your crafting experience. The emergence of the home laser cutter machine has transformed the way hobbyists and professionals alike approach their projects. This innovative technology offers precision, versatility, and efficiency that traditional crafting methods simply cannot match. Whether you're designing intricate designs, customizing gifts, or creating unique home decor, a home laser cutter machine provides the ability to materialize your ideas with professional-quality results.

The convenience of using a home laser cutter machine cannot be overstated. It empowers users to easily carve, engrave, or cut various materials such as wood, acrylic, and leather, all from the comfort of their own home. As these machines become more accessible and user-friendly, they open up a world of possibilities for individuals looking to express themselves creatively. Furthermore, integrating a laser cutter into your DIY toolkit not only enhances your crafting capabilities but also saves time and reduces material waste, allowing you to focus more on your artistic vision.

In this exploration of the benefits of choosing a home laser cutter machine for your projects, we will delve into how this advanced tool can elevate your DIY endeavors, making crafting an enjoyable and efficient experience. Whether you're a seasoned maker or just starting, the advantages of adopting a laser cutter are clear: it allows for greater creativity, precision, and the opportunity to bring your visions to life like never before.

Benefits of Using a Home Laser Cutter for DIY Projects

A home laser cutter machine can be a game-changer for DIY enthusiasts, offering precision and versatility that traditional tools often can't match. According to a report by Smithers Pira, the global laser cutting market is expected to reach over $6 billion by 2024, driven by the growing demand for personalization in various projects. This rise reflects a trend where many hobbyists and small businesses seek to harness the cutting-edge technology of laser cutters to bring their creative visions to life.

One of the key benefits of using a home laser cutter is the level of accuracy it allows. Laser machines can achieve cutting tolerances of up to 0.1 mm, making them ideal for intricate designs and detailed work. Furthermore, the ability to work with a variety of materials—including wood, acrylic, and fabric—opens up a myriad of possibilities for DIY projects. The ease of use associated with modern laser cutters is backed by a survey from the Craft and Hobby Association, which indicates that over 60% of crafters who invested in a laser cutter reported enhanced productivity and the ability to take on more complex projects. These machines empower users to experiment and innovate in ways that traditional woodworking or crafting methods often limit.

Types of Materials Suitable for Laser Cutting in Home Projects

When embarking on DIY projects, selecting the right materials for a home laser cutter can greatly enhance your creativity and efficiency. One of the most popular materials suitable for laser cutting is plywood. Thin sheets of plywood can be easily cut and engraved, making them ideal for crafting intricate designs, from decorative items to practical components in furniture projects. The versatility of plywood allows for a wide range of finishes and appearances, enabling hobbyists to achieve professional-looking results in the comfort of their own homes.

Another excellent option for laser cutting is acrylic. Acrylic sheets come in various colors and thicknesses, making them perfect for signage, displays, and artistic creations. The precision of laser cutting can yield clean edges that eliminate the need for additional finishing, providing a polished look straight from the machine. Additionally, materials like leather and fabric can be used to create custom items such as wallets, bags, or unique home decor. The ability to cut and engrave these materials allows for personalized touches that reflect the creator's style while ensuring durability and functionality.

Key Features to Consider When Choosing a Home Laser Cutter

When considering a home laser cutter for your DIY projects, there are key features that can significantly enhance your experience and outcomes. One of the most important aspects to look for is the cutting power, typically measured in watts. According to a recent industry report, machines with higher wattage, such as those in the range of 40 to 100 watts, can cut through thicker materials, making them more versatile for various applications. A machine with at least 40 watts is recommended for hobbyists who aim to work with materials like wood, acrylic, and certain metals.

Another critical factor is the bed size of the laser cutter. A larger bed allows for more substantial projects and the ability to cut multiple items simultaneously, which can save time and increase productivity. Industry trends suggest that a work area of at least 12x20 inches is ideal for most DIY enthusiasts, enabling the creation of everything from custom furniture to decorative items. Furthermore, consider the software compatibility; many laser cutters come equipped with user-friendly software that facilitates design and editing, making the process accessible even for beginners. Notably, ease of use and software integration can significantly reduce the learning curve, ultimately enhancing your DIY creative journey.

Why You Should Choose a Home Laser Cutter Machine for Your DIY Projects - Key Features to Consider When Choosing a Home Laser Cutter

| Feature |

Description |

Importance Level |

| Laser Type |

CO2 lasers are ideal for cutting and engraving a wide range of materials. |

High |

| Power Output |

Higher wattage allows for faster cutting and the ability to work with thicker materials. |

Medium |

| Work Area Size |

A larger work area allows for more flexibility in projects and larger materials. |

High |

| User Interface |

Intuitive controls and software compatibility make the machine easier to use. |

Medium |

| Safety Features |

Emergency stop, ventilation, and protective covers are essential for safe operation. |

High |

| Portability |

Lightweight and compact designs are easier to move and store. |

Low |

| Price |

Budget considerations vary widely; balance features with cost. |

High |

Cost-Effectiveness of Home Laser Cutting vs. Professional Services

When it comes to DIY projects, the cost-effectiveness of investing in a home laser cutter machine can significantly outweigh the expenses associated with professional services. According to a report by IBISWorld, the average hourly rate for laser cutting services ranges from $75 to $150, depending on the intricacy of the design and material used. For enthusiasts who frequently engage in crafting, this cost can accumulate quickly, making professional services less viable long-term.

In contrast, a home laser cutter machine requires a one-time investment typically ranging from $200 to $3,000. This upfront cost can be offset by the savings made on multiple projects. A study by Technavio estimates that owning a laser cutter can reduce crafting costs by up to 40%, especially for users who frequently require cutting services. Moreover, having a laser cutter at home allows for greater creativity and customization, enabling users to experiment with various materials and designs without incurring extra charges. The automation and precision offered by these machines can lead to both material savings and enhanced project quality, proving that home laser cutters are a smart choice for dedicated DIYers.

Cost-Effectiveness of Home Laser Cutting vs. Professional Services

This chart illustrates the average cost comparison between purchasing a home laser cutter and utilizing professional laser cutting services. Investing in a home laser cutter can significantly reduce costs for DIY projects over time.

Safety Tips and Best Practices for Using Laser Cutters at Home

When considering a home laser cutter for DIY projects, safety should be a primary concern.

According to a report by the National Institute for Occupational Safety and Health (NIOSH), improper handling of laser cutters can lead to serious injuries, including burns and eye damage.

It’s crucial for users to wear appropriate protective gear, such as safety goggles specifically designed for laser use, to shield their eyes from harmful beams.

Furthermore, maintaining a clean workspace is essential to prevent flammable materials from being ignited by laser sparks.

In addition to personal safety, best practices in operating laser cutters can significantly improve project outcomes.

The American Society of Mechanical Engineers (ASME) recommends conducting thorough research on materials before cutting.

Different materials—like acrylic, wood, or metal—have varying thresholds for laser cutting, which can affect precision and quality.

It's also advisable to perform regular maintenance checks on the machine to ensure it operates efficiently.

Keeping the optics clean and calibrating the settings can extend the lifespan of the cutter and enhance safety during operation.

By adhering to these safety tips and best practices, enthusiasts can enjoy the creative potential of home laser cutting while minimizing risks.