10 Essential Tips for Choosing a CO2 Laser Cutting Machine

Choosing the right CO2 laser cutting machine is vital for success in various industries. According to industry expert Dr. Emily Chen, “Selecting the right machine not only enhances precision but also boosts productivity.” This statement resonates with many in the laser cutting field, highlighting the machine's impact on efficiency.

When exploring options, consider the machine's specifications and capabilities. A powerful laser cutter can achieve intricate designs. Look for reliable brands known for durability and performance. Many users report mixed experiences due to improperly matched machines and applications. It's crucial to assess your specific needs.

Simultaneously, think about the machine's ease of use. Complicated interfaces can lead to frustration. Experts recommend testing the controls before making a purchase. Ultimately, investing time in research can lead to better choices, avoiding potential setbacks in your cutting projects.

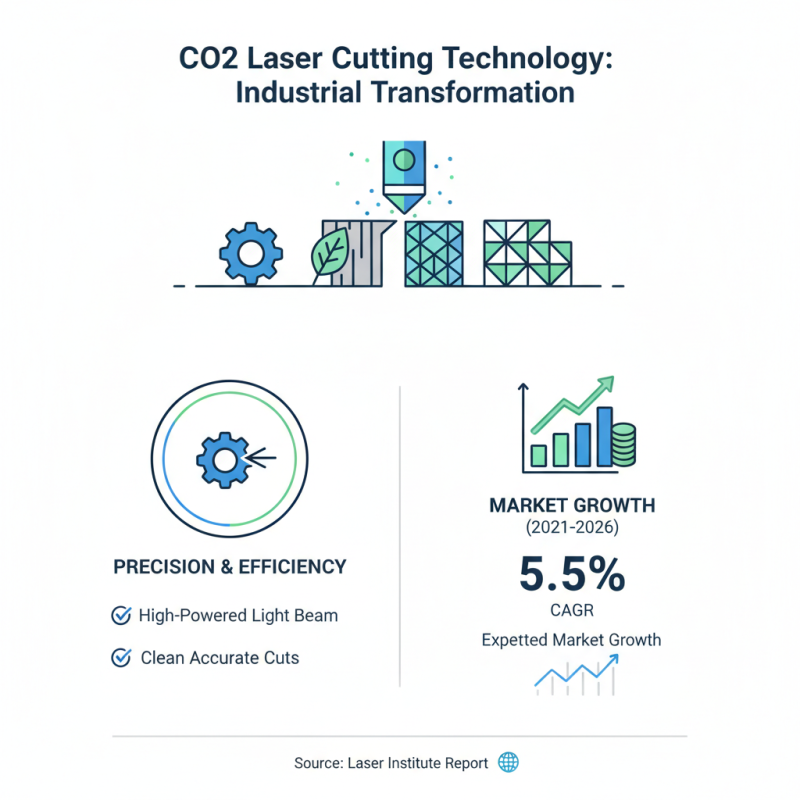

Understanding CO2 Laser Cutting Technology and Its Applications

CO2 laser cutting technology has transformed various industries. It uses a high-powered beam of light to cut through materials like wood, acrylic, and metal. According to a report by the Laser Institute, the market for laser cutting machines is expected to grow at a CAGR of about 5.5% from 2021 to 2026. This technology is cherished for its precision and efficiency.

Applications of CO2 lasers extend beyond manufacturing. They are widely used in the signage industry, for etching designs on products, and even in the medical sector for certain surgical procedures. The versatility of CO2 lasers makes them attractive. However, one must consider the learning curve involved in operating these machines. Some users report difficulties in mastering the software required for design and operation.

Moreover, maintenance can often be overlooked. Regular checks on optics and alignment are crucial for optimal performance. Many operators find themselves troubleshooting issues that could have been prevented with routine upkeep. Awareness of these challenges is important. Even a small oversight can lead to substantial downtime and increased costs.

Key Factors to Consider: Power, Speed, and Precision in Laser Machines

Choosing a CO2 laser cutting machine requires careful consideration of several key factors, especially power,

speed, and precision.

Power is crucial because it determines the thickness of the material the machine can cut.

Machines with higher wattage can handle thick materials. However, too much power can cause excessive burn marks.

Finding a balance is important; you want power without damaging your work.

Speed is another critical factor. A faster machine can increase productivity. Yet, high speed sometimes compromises cut quality.

It’s essential to evaluate the types of projects you will work on. If intricate designs are common, a slower speed with greater precision may be beneficial.

The right speed ensures clean edges and detailed patterns, meeting your project's needs.

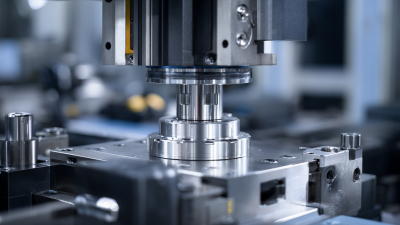

Precision ties everything together. A precise laser cutting machine ensures accurate cuts every time.

It’s vital for detailed work. Look for machines that offer adjustable settings. Some users may find it challenging to achieve perfection.

Experimenting with settings can yield better results, but it might take time.

A machine that combines the right power, speed, and precision will serve you well in the long run.

Evaluating the Build Quality and Durability of CO2 Laser Cutters

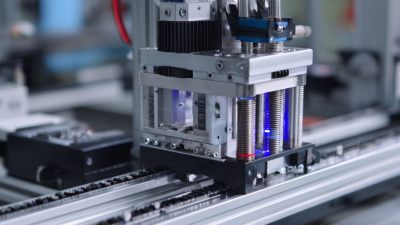

When choosing a CO2 laser cutting machine, the build quality and durability should be high on your checklist. A sturdy frame is essential. Look for a device that is heavy and well-constructed. Thin metal parts or flimsy components can jeopardize performance. This could lead to misalignments during cutting. It’s wise to physically inspect the machine if possible.

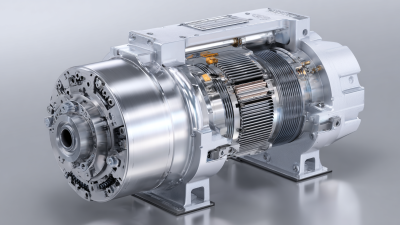

Pay attention to the components used in the assembly. High-quality motors and circuitry often mean a longer lifespan. In contrast, cheaper materials may wear out faster, leading to frequent repairs. It’s also important to consider the cooling system. An efficient cooling mechanism prevents overheating, thus enhancing durability. Some designs, while compact, may sacrifice robustness. That's a trade-off worth noting.

Regular maintenance plays a crucial role in longevity, too. Some users forget this aspect. Dust and debris can settle into sensitive areas, affecting performance. Moreover, warranties can vary significantly. A solid warranty often indicates confidence in the product's durability. However, read the fine print carefully. Knowing the limitations is just as important as understanding the strengths.

Evaluating Build Quality and Durability of CO2 Laser Cutters

Assessing Software Compatibility and Ease of Use for Operators

When choosing a CO2 laser cutting machine, software compatibility is crucial. The software should integrate smoothly with the hardware. Look for a user-friendly interface. Operators often complain about complex software, which hinders productivity. A clear, intuitive design can make a significant difference. It’s essential to assess the learning curve involved. If the software is too complicated, operators may struggle to adapt.

Ease of use should go beyond just learning the software. Check if there are ample support resources available. Documentation, tutorials, and customer support are vital. Operators should feel confident using the machine regularly. A lack of resources can lead to frustration and errors. Additionally, consider how often the software is updated. Frequent updates can improve functionality but may also require retraining.

Lastly, don’t overlook the importance of trial periods. Testing the software before committing can reveal many issues. Operators should evaluate performance in real-world scenarios. This hands-on experience might highlight challenges not discussed online. Taking the time to assess software compatibility will pay off in smoother operations.

Budgeting: Initial Costs vs. Long-Term Maintenance and Operating Expenses

When considering a CO2 laser cutting machine, budgeting is crucial. Initial costs often catch buyers off guard. High-quality machines can be a significant investment. Be prepared to spend anywhere from a few thousand to tens of thousands of dollars. It's essential to evaluate if the machine's capabilities align with your needs. Test it if possible.

Long-term maintenance and operating expenses can add up quickly. Routine maintenance is a necessary cost that shouldn’t be overlooked. Parts wear out and need replacement. Be mindful of power consumption, as energy costs can fluctuate significantly. Some users fail to consider these expenses until it’s too late. Think about the total cost of ownership, not just the upfront price. Engage with reviews and feedback from current users to get a better sense of potential pitfalls and common issues.

10 Essential Tips for Choosing a CO2 Laser Cutting Machine - Budgeting: Initial Costs vs. Long-Term Maintenance and Operating Expenses

| Feature |

Initial Cost ($) |

Annual Maintenance Cost ($) |

Operating Expenses ($/hour) |

Lifespan (Years) |

| Entry-Level Machine |

2,500 |

150 |

5 |

5 |

| Mid-Range Machine |

5,000 |

300 |

10 |

7 |

| Industrial Machine |

15,000 |

600 |

20 |

10 |

| High-Power Machine |

25,000 |

1,200 |

30 |

15 |