Why Direct Drive Linear Motors Are Revolutionizing Automation and Manufacturing

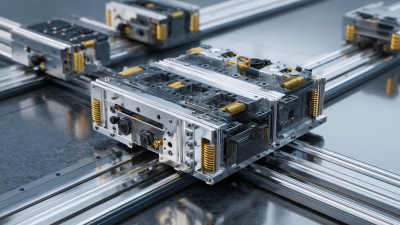

The rise of direct drive linear motors has ushered in a new era in automation and manufacturing, transforming how industries operate and enhancing overall efficiency. These innovative systems eliminate the need for traditional gearing and mechanical linkages, allowing for a more streamlined and direct transfer of power. As a result, manufacturers are experiencing significant gains in speed, precision, and reliability. The ability to achieve high acceleration and deceleration rates without the inertia often found in conventional motors presents unprecedented advantages for assembly lines and manufacturing processes.

Furthermore, the incorporation of direct drive linear motors into automation not only optimizes production cycles but also minimizes maintenance needs. Such systems are inherently simpler and more robust, reducing wear and tear over time and lowering the total cost of ownership. This evolution in technology is laying the groundwork for smarter manufacturing environments, where adaptability and responsiveness to changes in demand are paramount. As industries continue to embrace automation, understanding the pivotal role of direct drive linear motors will be crucial for remaining competitive in a rapidly changing landscape.

Overview of Direct Drive Linear Motors in Automation

Direct drive linear motors (DDLMs) are transforming the landscape of automation and manufacturing by providing unparalleled precision, speed, and efficiency. Unlike traditional motor systems that rely on mechanical components like gears or belts, DDLMs eliminate these intermediaries, allowing for direct motion transfer. This results in reduced wear and tear, lower maintenance costs, and minimized energy losses. With their ability to generate high thrust and rapid acceleration, DDLMs enable faster cycle times and enhanced productivity in various industrial applications.

In the realm of automation, DDLMs facilitate advanced control over positioning and motion. They are particularly valuable in applications requiring high accuracy, such as robotics, conveyor systems, and CNC machining. By integrating with sophisticated control systems and software, DDLMs can execute complex tasks with minimal lag, contributing to smoother operations and improved outcomes. As industries increasingly seek to optimize performance and adapt to dynamic market demands, the adoption of direct drive linear motors is poised to expand, paving the way for innovative automation solutions that push the boundaries of manufacturing capabilities.

Why Direct Drive Linear Motors Are Revolutionizing Automation and Manufacturing

| Feature |

Description |

Advantages |

Applications |

| High Precision |

Maintains precise positioning without mechanical gears. |

Increased accuracy in manufacturing processes. |

Robotics, CNC machines, and 3D printing. |

| High Speed |

Capable of fast acceleration and deceleration. |

Reduced cycle times and improved throughput. |

Material handling and automated assembly lines. |

| Low Maintenance |

Fewer moving parts leads to less wear and tear. |

Lower operational costs and downtime. |

Long-term industrial automation solutions. |

| Energy Efficiency |

Direct drive motors reduce energy losses. |

Lower energy costs and environmental impact. |

Manufacturing processes focusing on sustainability. |

| Compact Design |

Lesser need for additional infrastructure. |

Space-saving installations in factories. |

Tight spaces in manufacturing and assembly. |

Key Advantages of Direct Drive Linear Motors in Manufacturing

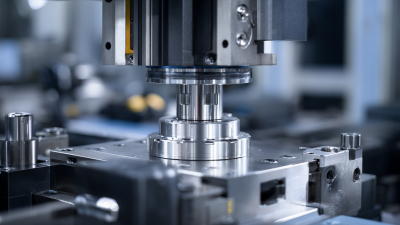

Direct drive linear motors are transforming the landscape of automation and manufacturing with a host of key advantages that enhance productivity and efficiency. One of the primary benefits of these motors is their ability to provide precise and rapid movement. Unlike traditional systems that rely on gearboxes and belts, direct drive linear motors deliver power directly to the load, resulting in faster response times and reduced mechanical lag. This precision is crucial in applications requiring tight tolerances and high repeatability, allowing manufacturers to achieve superior quality in their products.

Another significant advantage is the reduction in maintenance and operational costs. By eliminating the need for mechanical components like gears and pulleys, direct drive systems minimize wear and tear, reducing the frequency and costs associated with maintenance. This reliability not only lowers the total cost of ownership but also enhances uptime, enabling manufacturers to operate more efficiently. Additionally, fewer moving parts contribute to a smaller ecological footprint, aligning with modern sustainability goals within the industry. As automation continues to evolve, the advantages of direct drive linear motors position them as a pivotal technology in the future of manufacturing.

Applications of Direct Drive Linear Motors in Various Industries

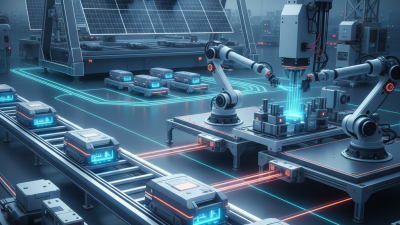

Direct drive linear motors are transforming the landscape of various industries by enhancing precision and efficiency. In manufacturing environments, these motors are increasingly employed in automation systems for their ability to provide direct motion without the need for mechanical components like gears and belts. This results in reduced wear and tear, lower maintenance costs, and improved reliability. Applications include assembly lines, where rapid and coordinated movements are essential for throughput, and CNC machines, where high accuracy is crucial for intricate machining processes.

In sectors such as transportation and material handling, direct drive linear motors facilitate rapid movement of goods over long distances. Their smooth and quiet operation is particularly beneficial in environments like warehouses or airports, where noise reduction enhances the overall experience. Furthermore, industries like robotics are leveraging these motors for precise control over robotic arms and other moving components, enabling complex tasks ranging from delicate fabrication to heavy-duty lifting. As these applications continue to expand, direct drive linear motors are set to become a cornerstone of modern automation and manufacturing practices.

Comparison with Traditional Motor Systems in Automation

Direct drive linear motors are gaining substantial traction in the automation and manufacturing sectors, offering significant advantages over traditional motor systems. Conventional motors, such as stepper or servo systems, often rely on mechanical components like gears and belts, which can introduce backlash, wear, and maintenance challenges. In contrast, direct drive linear motors utilize magnetic fields to create motion, resulting in smoother operation with higher precision.

According to industry reports, manufacturers can achieve positioning accuracy of up to 1 micron with direct drive systems, which is a notable improvement compared to the typical accuracy of 5 to 20 microns seen in traditional systems.

Furthermore, direct drive systems offer enhanced energy efficiency. Research indicates that direct drive linear motors can be up to 90% more efficient than traditional motor systems, primarily due to their reduced mechanical losses and lower inertia. This efficiency translates into lower operating costs and contributes to more sustainable manufacturing practices. As production facilities increasingly focus on minimizing downtime and maximizing output, the seamless integration of direct drive technology not only streamlines operations but also supports the move towards smart factories, where adaptability and precision are paramount. The adoption of direct drive linear motors is expected to grow significantly, with market analyses projecting an annual growth rate of approximately 8% in the coming years, underscoring their transformative potential in the industry.

Future Trends and Innovations in Direct Drive Linear Technology

The evolution of direct drive linear technology is paving the way for significant innovations in

automation and manufacturing industries. As manufacturing processes demand

increased precision and efficiency,

direct drive linear motors are emerging as a formidable solution. By eliminating the complexities of traditional

mechanical systems, these motors provide unparalleled accuracy and faster cycle times, making them ideal for

applications ranging from semiconductor fabrication to high-speed packaging.

Future trends indicate a growing integration of direct drive linear technology with advanced control systems

and artificial intelligence. This convergence allows for

real-time data processing and adaptive control, optimizing performance based on

varying operational conditions. Furthermore, as the Internet of Things (IoT) becomes more prevalent,

direct drive systems can seamlessly connect to smart networks, enhancing predictive maintenance and reducing

downtime.

Innovations in materials science, such as lightweight composites,

are also set to enhance the efficiency and

capabilities of these motors, making them more versatile across different manufacturing environments.