How to Choose the Best CNC Fiber Laser Cutting Machine for Your Needs

Choosing the right CNC fiber laser cutting machine can significantly impact the efficiency and quality of your manufacturing processes. As industries increasingly adopt advanced cutting technologies, understanding the key factors that influence the selection of these machines is essential for optimizing production. With various models and features available, it can be challenging to determine which CNC fiber laser cutting machine best suits your specific needs and applications.

To navigate this landscape, it's important to consider factors such as the machine's power output, cutting speed, and material compatibility. Additionally, evaluating the machine's technical specifications, such as its control system and ease of maintenance, will help ensure that your investment aligns with your long-term operational goals. By making an informed choice, businesses can enhance productivity, reduce operational costs, and achieve greater precision in their cutting tasks.

Whether you are a small workshop or a large manufacturing facility, understanding how to choose the best CNC fiber laser cutting machine for your needs will empower you to stay competitive in an ever-evolving market. This guide will provide insight into essential considerations that will aid in making the right decision for your laser cutting capabilities.

Understanding Your Cutting Requirements: Material and Thickness Considerations

When selecting a CNC fiber laser cutting machine, understanding your cutting requirements is crucial, particularly in relation to the materials you plan to work with and their respective thicknesses. Different materials, such as metal, wood, and plastic, possess unique properties that affect how they respond to laser cutting. For instance, metals like stainless steel and aluminum require specific laser power settings and protective measures to achieve clean, precise cuts. Conversely, materials like acrylic may require less power but can be more susceptible to burning if not handled correctly.

Furthermore, the thickness of the material also plays a significant role in determining the appropriate machine specifications. Thicker materials generally necessitate higher wattage lasers to penetrate effectively, whereas thinner materials can often be cut using lower power settings without compromising quality. It’s essential to assess the range of thicknesses you intend to work with and ensure the CNC fiber laser cutting machine you consider can accommodate those requirements. By carefully evaluating both the materials and their thicknesses, you will be better equipped to choose a machine that meets your specific production needs, ensuring efficiency and output quality in your projects.

How to Choose the Best CNC Fiber Laser Cutting Machine for Your Needs

| Material Type |

Max Thickness (mm) |

Cutting Speed (m/min) |

Power (W) |

Precision (mm) |

| Mild Steel |

25 |

10 |

1000 |

0.1 |

| Stainless Steel |

20 |

8 |

1500 |

0.05 |

| Aluminum |

15 |

12 |

2000 |

0.07 |

| Copper |

10 |

5 |

1200 |

0.1 |

| Brass |

8 |

6 |

1800 |

0.1 |

Evaluating Laser Power: Choosing Between 500W to 20kW Options

When selecting a CNC fiber laser cutting machine, evaluating laser power is crucial, as it directly impacts the machine's performance and capabilities. The power range typically varies from 500W for entry-level systems to 20kW for high-end applications. A 500W laser cutter is suitable for thin materials, making it ideal for small shops or individuals focusing on precise cuts in metals like aluminum or stainless steel. These machines are user-friendly and efficient for light-duty tasks, ensuring a balance between cost and functionality.

On the other hand, machines equipped with higher wattage, such as 10kW and 20kW, provide the ability to cut through thicker materials and enhance productivity. They are designed for industrial applications, where speed and quality are paramount. With higher power, the laser can process materials that range from mild steel to more complex alloys, offering versatility for various manufacturing needs. Nevertheless, as power increases, so does the investment; thus, it's essential to assess your specific cutting requirements, budget, and operational capacity to determine the optimal power level for your CNC fiber laser cutting machine.

Assessing Work Area Size: Ensuring Adequate Space for Production

When selecting a CNC fiber laser cutting machine, one critical aspect to consider is the size of the work area. An adequately sized work area is essential for enhancing production efficiency and accommodating various materials. According to a report from the International Federation of Robotics, operational space can significantly impact workflow; a well-designed layout minimizes the need for manual handling and maximizes throughput. Thus, evaluating your current and future production demands should be a priority.

When assessing your work area size, keep in mind the types of materials you will be cutting. Larger materials may require a more extensive work surface to allow for dynamic movement and precise cuts without interruption. It's often recommended to factor in an additional 20-30% space beyond your largest material size to enable ease of operation and machine access during maintenance.

Tips: Consider the versatility of your work area — can it accommodate various projects, or is it too specialized? Also, think about how the layout can facilitate better workflow, potentially integrating roll-out tables or movable storage solutions. Lastly, remember to account for ventilation and safety zones when planning your CNC machine's placement; this ensures not only optimal performance but also compliance with safety regulations.

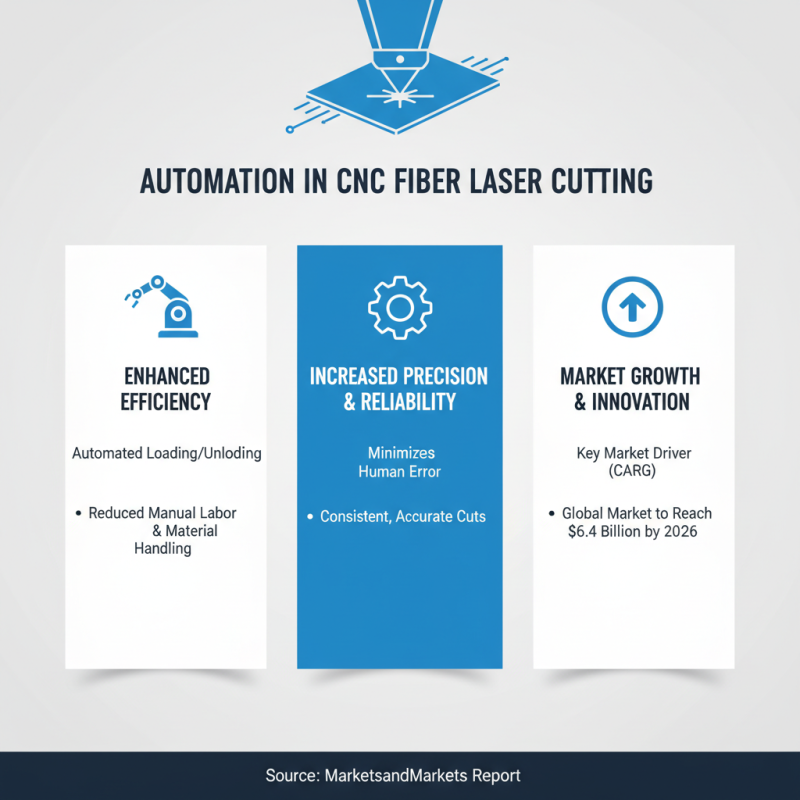

Exploring Automation Features: Enhancing Efficiency and User-Friendliness

When selecting a CNC fiber laser cutting machine, the automation features play a pivotal role in enhancing both efficiency and user-friendliness. Modern machines are equipped with advanced automation technologies, such as automated loading and unloading systems, which significantly reduce manual labor and material handling time. According to a report by MarketsandMarkets, the global laser cutting market is expected to reach $6.4 billion by 2026, with automation being a key driver of this growth. Integrating smart automation not only streamlines the workflow but also minimizes the chances of human error, ensuring high precision in complex cutting tasks.

Tips for choosing the right automation features include evaluating the specific needs of your production environment. If your operations involve frequent job changes, look for machines with flexible automation options that can handle varying material sizes and thicknesses. Additionally, consider user-friendly interfaces that simplify programming tasks and allow operators to quickly adapt to different projects. With the right features, you can significantly boost productivity levels and reduce downtime.

The advantages of incorporating automation extend beyond efficiency; they also enhance user experience. Features such as real-time monitoring and predictive maintenance alerts help operators maintain optimal machine performance with minimal intervention, aligning with the industry trend towards IoT integration in manufacturing. As reported by McKinsey, companies that leverage such automation can see productivity gains of up to 30%. Investing in a CNC fiber laser cutting machine with robust automation capabilities can facilitate this transition, driving your operational success in the competitive market.

Evaluating Manufacturer Support: Importance of Warranty and Service Options

When investing in a CNC fiber laser cutting machine, evaluating the manufacturer’s support is crucial for ensuring long-term satisfaction and operational efficiency. A key aspect of this support is the warranty offered on the machine. A comprehensive warranty not only protects your investment but also reflects the manufacturer's confidence in the durability and reliability of their equipment. It’s essential to examine the length of the warranty and what it covers, as this will vary between manufacturers. A solid warranty alleviates concerns regarding potential repairs and parts replacement down the line, providing peace of mind as you integrate the machine into your operations.

In addition to the warranty, the availability of service options is another critical factor in manufacturer support. Prompt and reliable service can significantly reduce downtime, which is especially important in a production environment where efficiency is paramount. Consider the service network of the manufacturer, including the accessibility of technicians, parts availability, and the speed at which they can respond to service requests. Some manufacturers may offer on-site support, while others might provide remote assistance. Understanding these service dynamics can help you choose a CNC fiber laser cutting machine that not only meets your technical specifications but also comes with the necessary support to keep your operations running smoothly.