2025 Top 10 CNC Laser Cutters That Will Revolutionize Your Business

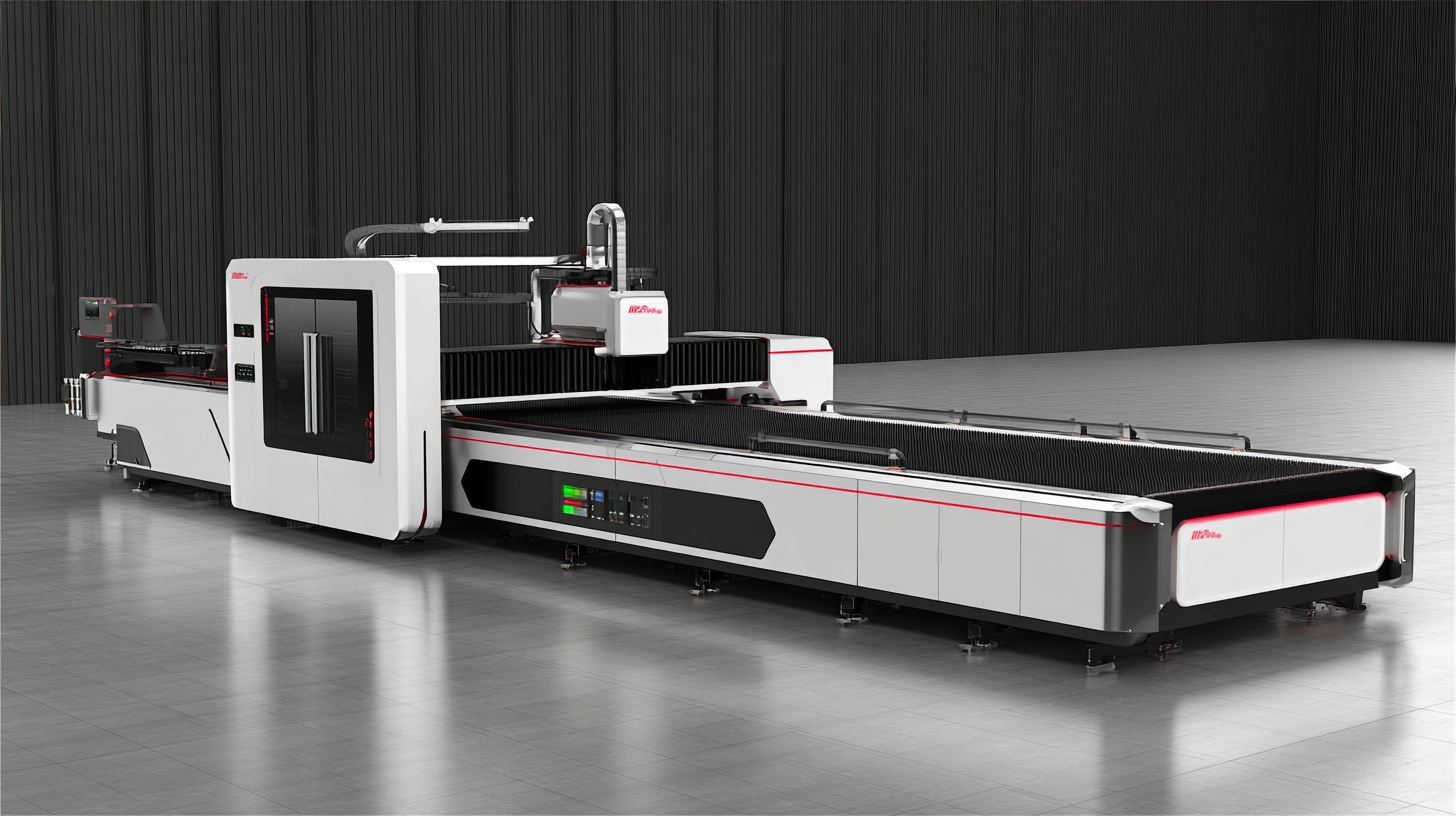

In today's rapidly evolving manufacturing landscape, businesses are continually seeking innovative solutions to enhance their production capabilities and gain a competitive edge. One such transformative technology is the CNC laser cutter, a powerful tool that combines precision, efficiency, and versatility. As we look ahead to 2025, it is crucial to identify the top CNC laser cutters that have the potential to revolutionize operations across various industries. These advanced machines not only streamline processes but also improve the quality of products, allowing companies to meet the increasing demands of the market.

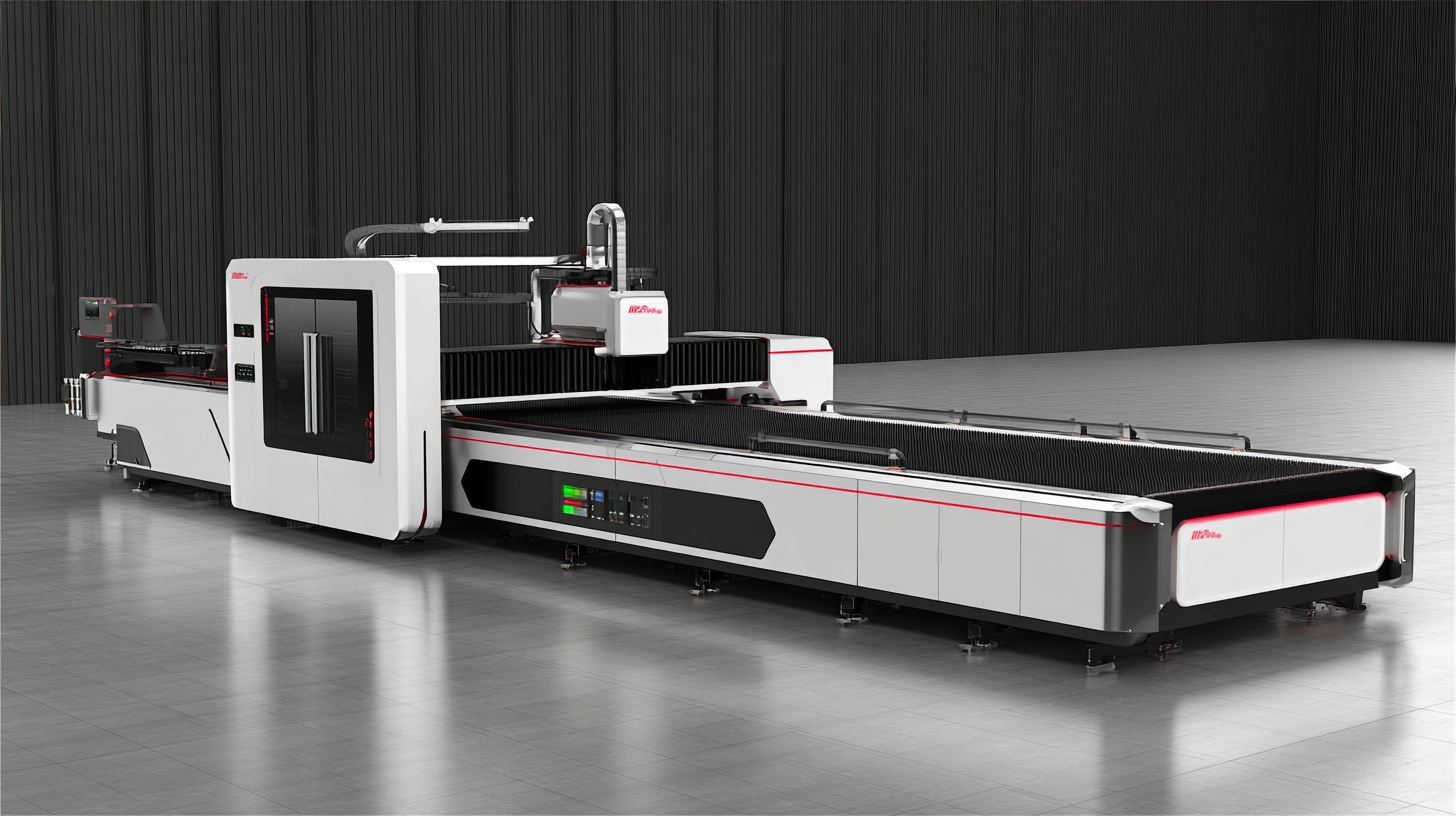

In this article, we will delve into the top 10 CNC laser cutters set to dominate the industry in the coming years. Each selected machine features state-of-the-art technology, user-friendly interfaces, and exceptional cutting capabilities. By exploring these cutting-edge tools, businesses can better understand how to integrate CNC laser cutting into their operations, leading to significant improvements in efficiency and output quality. Additionally, we will provide practical tips and insights to help you choose the right CNC laser cutter that aligns with your specific business needs and objectives. Prepare to embark on a journey towards innovation and excellence as we unveil the future of CNC laser cutting technology.

Transformative Features of 2025's Top CNC Laser Cutters

In 2025, the landscape of CNC laser cutting technology is set to undergo a significant transformation, thanks to the introduction of advanced features in top-rated machines. One standout feature is the integration of artificial intelligence, which enables these machines to learn from previous cuts and optimize settings for enhanced accuracy and speed. This not only reduces wastage but also ensures consistent quality across different materials, making it easier for businesses to scale their operations.

Additionally, improved software interfaces allow for greater customization and user-friendliness, ensuring that even those with minimal technical knowledge can operate these machines efficiently. Features like remote monitoring and predictive maintenance come standard in many models, allowing business owners to manage their cutting processes from anywhere and ensure minimal downtime.

Tips: Always check for compatibility with your existing software systems before making a purchase. Investing in a model with robust customer support can save you significant time and frustration down the line. Lastly, consider machines that offer modular features, as they allow you to expand functionality without needing a complete overhaul of your equipment.

Innovative Technology Advancements in CNC Laser Cutting

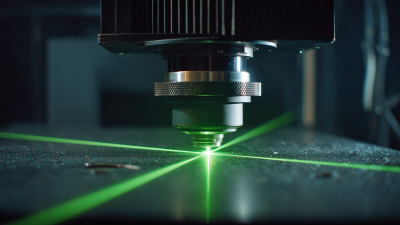

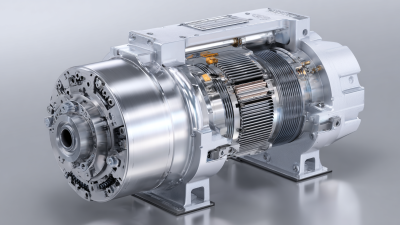

The realm of CNC laser cutting has witnessed significant technological advancements that are redefining the industry landscape. From enhanced precision to faster processing times, these innovations are not only streamlining operations but also allowing businesses to achieve an unparalleled level of customization. Features such as automated material handling systems and AI-driven software integration enable users to optimize their workflows, ensuring reduced waste and increased productivity.

Tip: Investing in training for your staff on the latest CNC software tools can maximize the benefits of these technological advancements. Ensure that your team is well-versed in programming and troubleshooting to harness the full potential of the new machinery.

Moreover, the introduction of hybrid CNC laser cutters combines fiber and CO2 technologies, offering versatility for different materials. This multifunctionality positions businesses to think beyond traditional limits and innovate further. As companies adopt these advanced technologies, they not only improve their production capabilities but also enhance their competitiveness in a rapidly evolving market.

Tip: Regularly updating and maintaining your CNC machinery will prevent downtime and extend the life of your equipment, ultimately leading to cost savings and improved efficiency.

2025 Top 10 CNC Laser Cutters Performance Comparison

Cost Efficiency: How CNC Laser Cutters Boost Your Bottom Line

CNC laser cutters have become indispensable tools for modern businesses, offering unparalleled cost efficiency that significantly boosts the bottom line. By utilizing advanced technology, these machines enable precise cutting with minimal material wastage. This precision not only reduces costs associated with rework and scrap but also enhances the overall quality of products. Companies can produce intricate designs at a fast pace, optimizing production timelines and ensuring timely delivery, which further contributes to customer satisfaction and repeat business.

Moreover, the versatility of CNC laser cutters allows businesses to diversify their offerings without substantial investment in different equipment. With the ability to cut various materials such as metal, wood, and plastics, companies can cater to a wider market, increasing their revenue streams. The initial investment in CNC laser cutting technology can be quickly recuperated through increased efficiency and reduced labor costs, making it a sound financial decision. As businesses strive for competitiveness in the market, investing in these cutting-edge tools becomes essential for sustained growth and profitability.

User-Friendly Interfaces: The Next Generation of Operator Experience

The CNC laser cutting industry is witnessing a significant transformation driven by advancements in user-friendly interfaces. As highlighted in the rise of human-machine interaction (HMI) technologies, the integration of intuitive dashboards and predictive analytics is reshaping how operators engage with machinery. According to recent industry reports, businesses that adopt these next-generation interfaces see up to a 30% increase in productivity thanks to reduced training times and improved operational efficiency.

The introduction of platforms similar to the new IPTV services demonstrates the growing emphasis on seamless user experience. Enhanced visual displays, easy navigation, and real-time feedback allow operators to make informed decisions quickly. These advancements mirror trends in other sectors, like smart manufacturing, where augmented reality systems are emerging as vital tools for enhancing operator efficacy. Reports indicate that companies utilizing augmented interfaces can achieve a 40% decrease in error rates, underscoring the importance of investing in such technologies as businesses aim to streamline their operations and enhance output quality.

Adapting CNC Laser Cutters for Various Industries in 2025

As the CNC machine market continues its robust growth, expected to soar from $101.22 billion in 2025 to $195.59 billion by 2032, various industries are poised to benefit significantly from advancements in CNC laser cutters. The integration of these cutting-edge machines is transforming manufacturing processes across sectors such as automotive, aerospace, and metal fabrication. With the demand for high-precision and multi-axis machining centers on the rise, CNC laser cutters are adapting to provide enhanced speed, accuracy, and flexibility that modern industries require.

In 2025, the emphasis on ultrafast laser stamping technology will further revolutionize industrial surface precision. This innovative approach combines rapid processing with the ability to fine-tune structural patterns via software, allowing for tailor-made solutions to intricate design challenges. The increasing application of artificial intelligence in CNC machining is redefining the landscape, enabling manufacturers to leverage data for optimal performance. As these technologies evolve, industries that adopt CNC laser cutters will significantly enhance their capabilities, driving productivity and competitiveness in the global market.